|

|

|

|

|

|

|

|

|

|

| EN 14399 Specification-NINGBO BOLT |

|

|

|

|

|

|

|

|

|

EN 14399 Specification

HIGH-STRENGTH STRUCTURAL BOLTING ASSEMBLIES FOR PRELOADING

Structural bolting in Europe comprises two technical solutions to achieve the necessary ductility of bolt/nut/washer assemblies. These solutions utilize different systems (HR and HV) of bolt/nut/washer assemblies, see table below. Both systems are well proved and it is up to the experts responsible for structural bolting whether they use the one or the other system.

|

Items |

Bolt/Nut/Washer Assembly |

Bolt/Nut/Washer Assembly |

|

System |

System HR |

System HV |

|

General Requirements |

EN 14399-1 |

|

|

Bolt/Nut Assembly |

EN 14399-3 |

EN 14399-4 |

|

Marking |

HR |

HV |

|

Property Class |

8.8/8 |

10.9/10 |

|

Washer(s) |

EN 14399-5 or EN 14399-6 |

EN 14399-5 or EN 14399-6 |

|

Marking |

H |

H |

|

Suitability Test for |

EN 14399-2 |

|

|

Preloading |

||

EN 14399 PARTS 1-10

There are currently 10 parts BS EN 14399 which are listed in the table below.

|

BS EN 14399 Part One |

General Requirements |

|

BS EN 14399 Part Two |

Suitability test for Preloading (assembly test)* |

|

BS EN 14399 Part Three |

Hexagon Bolt and Nut Assemblies (HR 8.8 and 10.9) |

|

BS EN 14399 Part Four |

Hexagon Bolt and Nut Assemblies (HV 10.9) |

|

BS EN 14399 Part Five |

Plain Washers |

|

BS EN 14399 Part Six |

Plain Chamfered Washers |

|

BS EN 14399 Part Seven |

Countersunk Bolt and Nut (HR 8.8 and 10.9) |

|

BS EN 14399 Part Eight |

Hexagon Fitted Bolt and Nut Assemblies (HV 10.9) |

|

BS EN 14399 Part Nine |

Direct Tension Indicators |

|

BS EN 14399 Part Ten |

Tension Control Bolt and Nut Assemblies (HRC 10.9) |

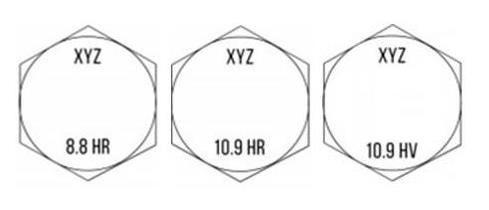

HEAD MARKINGS

Note: The `8.8 HR, 10.9 HR' means that the product was manufactured to BS EN 14399-3

Note: The `10.9 HV¨ means that the product was manufactured to BS EN 14399-4

EN14399-3 Class 8.8HR MECHANICAL PROPERTIES BOLTS

|

Items |

Stress Area |

Proof Load |

Ultimate Load |

Hardness Rockwell HRC |

|

|

2 |

Min. kN |

Min. kN |

|||

|

Dia. |

mm |

|

|

Min. |

Max. |

|

M12 |

84.3 |

50.7 |

70 |

22 |

32 |

|

M16 |

157 |

94.5 |

130 |

22 |

32 |

|

M20 |

245 |

147 |

203 |

23 |

34 |

|

M22 |

303 |

182 |

252 |

23 |

34 |

|

M24 |

353 |

212 |

293 |

23 |

34 |

|

M27 |

459.33 |

275 |

381 |

23 |

34 |

|

M30 |

561 |

337 |

466 |

23 |

34 |

|

M36 |

817 |

490 |

678 |

23 |

34 |

EN14399-3 Class 10.9HR MECHANICAL PROPERTIES BOLTS

|

Items |

Stress Area |

Proof Load |

Ultimate Load |

Hardness Rockwell HRC |

|

|

2 |

Min. kN |

Min. kN |

|||

|

Dia. |

mm |

|

|

Min. |

Max. |

|

M12 |

84.3 |

70 |

87.7 |

32 |

39 |

|

M16 |

157 |

130 |

163 |

32 |

39 |

|

M20 |

245 |

203 |

255 |

32 |

39 |

|

M22 |

303 |

252 |

315 |

32 |

39 |

|

M24 |

353 |

293 |

367 |

32 |

39 |

|

M27 |

459.33 |

381 |

477 |

32 |

39 |

|

M30 |

561 |

466 |

583 |

32 |

39 |

|

M36 |

817 |

678 |

850 |

32 |

39 |

EN14399-4 Class 10.9HV MECHANICAL PROPERTIES BOLTS

|

Items |

Stress Area |

Proof Load |

Ultimate Load |

Hardness Rockwell HRC |

|

|

2 |

|||||

|

Dia. |

mm |

Min. kN |

Min. kN |

Min. |

Max. |

|

M12 |

84.3 |

70 |

87.7 |

32 |

39 |

|

M16 |

157 |

130 |

163 |

32 |

39 |

|

M20 |

245 |

203 |

255 |

32 |

39 |

|

M22 |

303 |

252 |

315 |

32 |

39 |

|

M24 |

353 |

293 |

367 |

32 |

39 |

|

M27 |

459.33 |

381 |

477 |

32 |

39 |

|

M30 |

561 |

466 |

583 |

32 |

39 |

|

M36 |

817 |

678 |

850 |

32 |

39 |

|

||||||||||

|

Copyright © Ningbo Steel Bolt Co., Ltd All Rights Reserved |